Working closely with brilliant young designers and researchers comes close to our heart ever since we started VTL in 2017. Last November we had a chance to host Julia Kaleta from Amsterdam in our Viennese lab, just before the new lockdown measures were announced. Here is the final part of Julia’s personal blog about what she learned from our team members.

You can find Julia’s lessons 1 & 2 in the first part of her personal blog here.

Lesson 3. Demystification of chemistry is perceived in general as toxic.

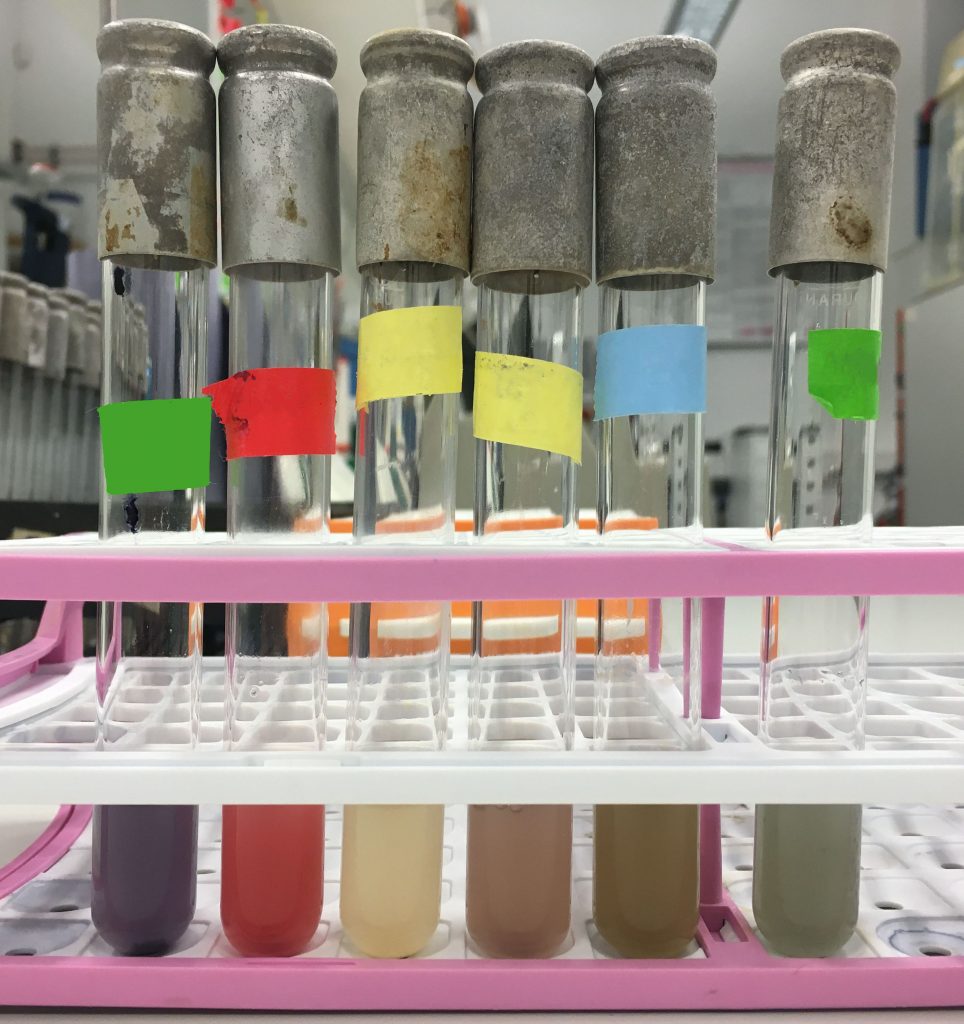

Personally and professionally, I am on a constant quest to find what makes the colour truly sustainable. Working with a natural material (in the case of bacterial dyeing it is a pigment produced by bacteria) is a common starting point to make colour production less harmful for the environment. But what about all of the processes which need to happen in order to prepare and grow the cultures (incubators and energy usage) or inactivate bacteria and fixate the colour on the fabric (with the use of heat or chemicals)?

In my opinion in order to assess the sustainability of a colour we need to look at the environmental footprint of all the steps and processes deployed while producing colour. I am someone who brings the facts about the dyeing industry’s influence on the environment and human wellbeing at the beginning of my talks, as a starting point for the debate about the role of colour in the fashion industry. We live in a world saturated with quick facts, data infographics and rapid changes of trends. In order to process this vast amount of information we jump to quick conclusions and still see surroundings in binary oppositions. As a result of constantly repeating the same facts, I have observed that an invisible link between the words ‘chemicals’ and ‘toxic’ was created. And what follows is an assumption that chemistry – which at the end of the nineteenth century achieved synthetic colours – is bad. Karin (founder and CEO of VTL) was the first person who taught me that not all chemicals are toxic when we had our first call in 2018. During my stay in Vienna last month, I approached Karin to find out more about her perspective on sustainable dyeing as well as her vision for the company’s goals. We quickly shared the same views that assumptions and stereotypes are influencing the perception of sustainable colours. Karin shared that the often asked question about the usage of the chemistry in their dyeing process misleads that using chemistry is bad. Vienna Textile Lab is heading towards biochemistry, as a bio-refinery, it develops bio-processes, in order to replace the conventional ways of dyeing (which relies on petroleum-based chemicals). Their sustainability strategy is aligned with the 12 principles of Green Chemistry.

‘You cannot delete the chemistry from the process of manufacturing dyes and pigments or from dyeing the textile, you need to improve it.’ Where shall we start? For example by recycling solvents. You will need to ensure to reduce or omit the production of toxic side products, even if the end product is not classified as toxic. Besides when you design the manufacturing process, you often use high temperature or pressure – this is very energy-consuming and therefore increases the CO2 footprint. These, amongst many others, are the approaches where VTL strives for optimization.

My stay in Vienna reassured me in the conclusion that in order to assess the sustainability of the colour you need to collaborate across the entire fashion supply chain. And in order to do it, you need to apply the whole spectrum of knowledge from both microbiology and chemistry as well as expertise in textile technology. It is because you not only work with natural pigments but also you need to know how they will bind with different fibres under specific conditions.

Fortunately, our collaboration is one of the many examples that what a few years ago was a vision from a trend book is already happening – interdisciplinary projects are going to re-shape the industry. Hence here are my key takeaways from the speed-dating with Vienna Textile Lab:

We need time to re-design dyeing processes. Slowing down is necessary to re-discover connection between the abundance of colourants in nature and our ways of using them in an innovative way.

Solutions for making fashion and textile industries more sustainable are being created as a result of the simultaneous knowledge exchange between science lab and an atelier, between a bioreactor and a cutting table – between team of people where expertise varies from the fields of green chemistry, bioprocess engineering, environmental chemistry, business development, project management and design, you name it,

We need to keep following Nature as the main leader, and see microorganisms as versatile and diverse as they are- we are all surrounded by them aid in making our bread, cheese, wine…and colour!

I would like to thank the team of Vienna Textile Lab for sharing their knowledge and co-editing the article.

Julia Kaleta from @atlasofsustainable